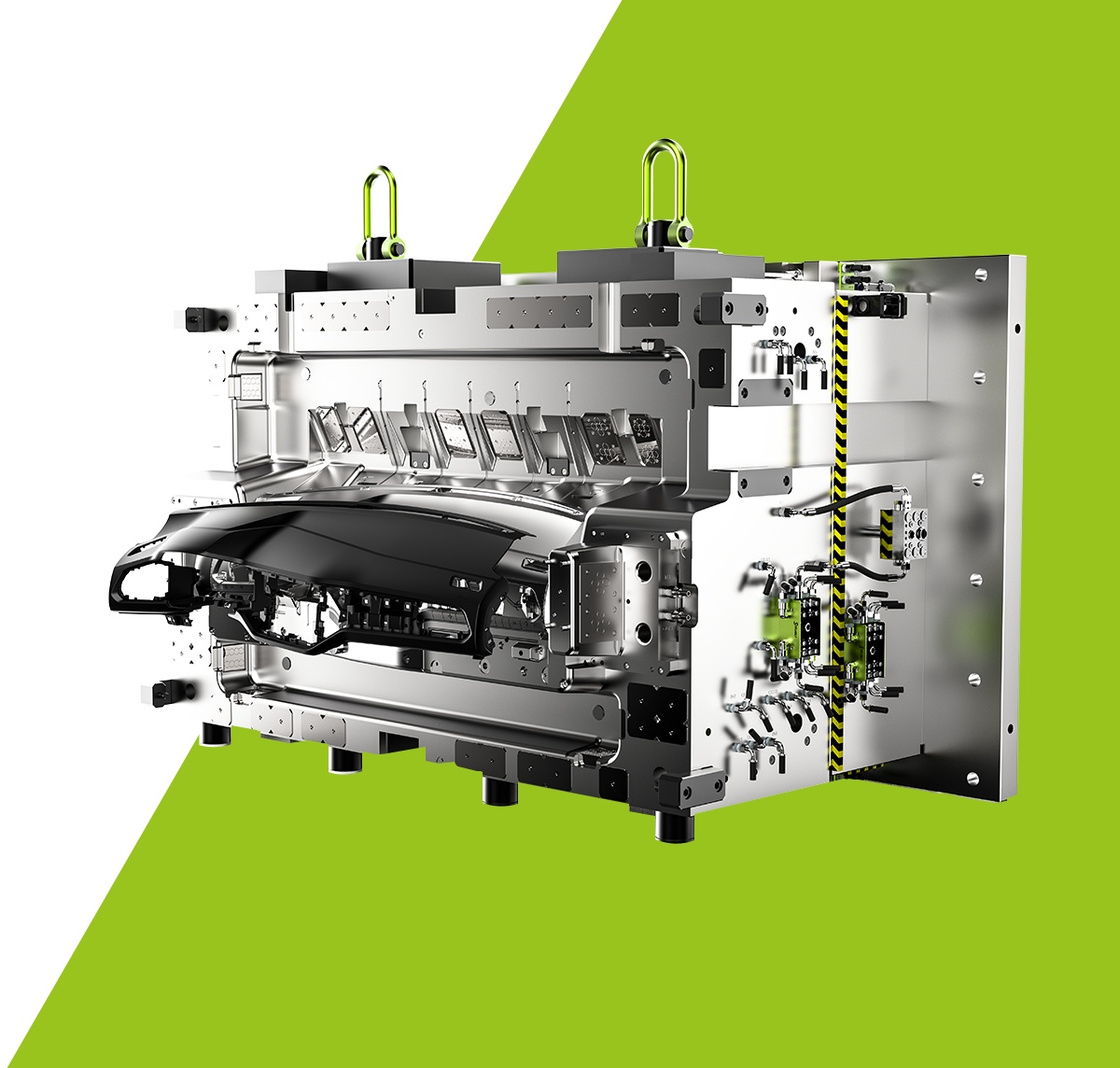

MOLDS PRODUCTION

MOLDIT Industries focuses its activity on the production of molds aggregated to the delivery of a high value added service.

MOLDIT Industries mold product is defined by the unique singularity and specificity to each project, incorporating 3 distinctive and essential phases for the delivery of a quality service, these being:

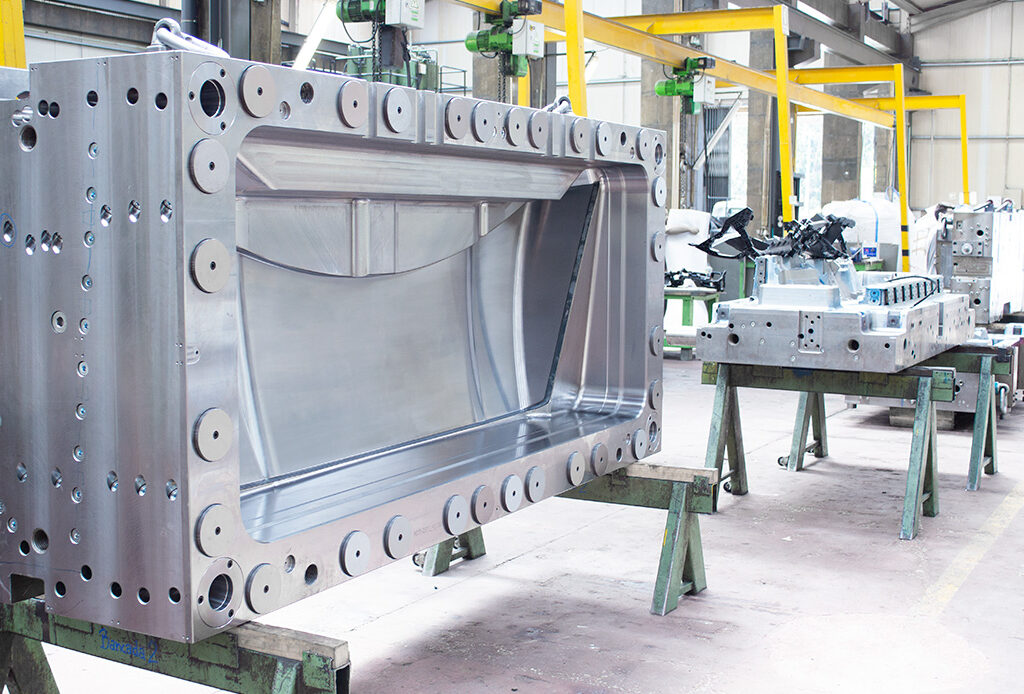

Molds Production: Guarantee of equipment and human skills needed in the implementation of production processes, where the confirmation of rigor is anticipated through the implementation of international standards certification.

Mold Test: Technological ability to test the mold internally, before its final move to the customer, optimizing the mold performance in advance.

Ramp-up: Follow-up by specialized technicians to the facilities defined by the customer in the initial phase of plastic parts production.

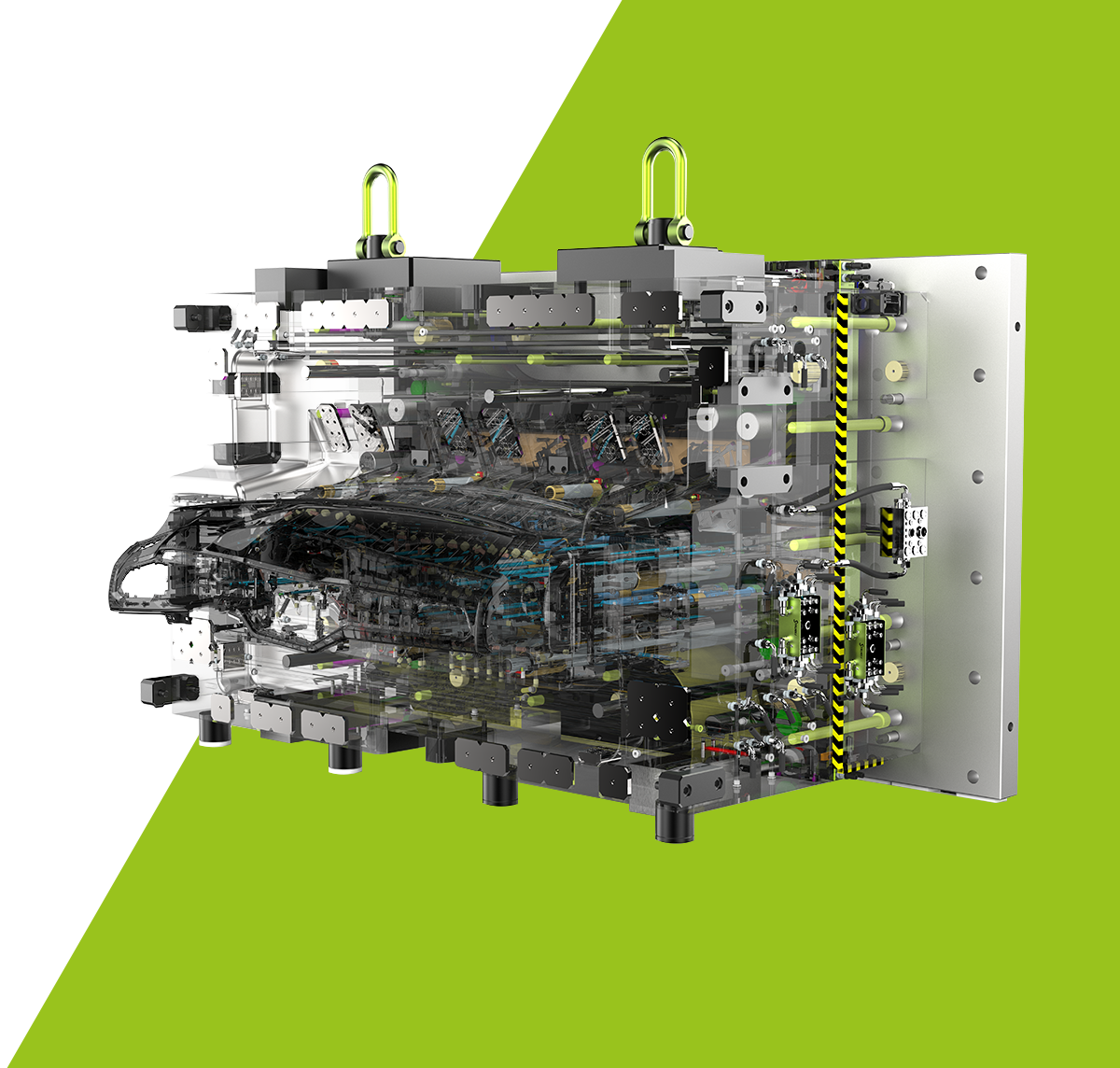

ENGINEERING

The Engineering Department is composed of a multidisciplinary team of professionals who develop innovative solutions.

The team, motivated by the confidence that customers place in their know-how and technological development capacity, is involved in part modelling, mold design development and injection process simulation.

TECHNOLOGIES

It consists of the casting of the polymer in order to mold it in the proper form and according to the purpose of the part.

The advantage of compression molding is its ability to mold large parts, relatively complex, with less mesh line production and less fibre degradation of injection molding length.

The 2-component process makes it possible to combine the application of different colors or materials in a single injection process, improving the design and operation of plastic parts.

The 3-component process makes it possible to combine the application of different colors or materials in a single injection process, improving the design and operation of plastic parts.

About injection molding process refers to an injection molding process that can manufacture products that are designed and combined with two or more core materials.

To achieve better quality levels in thermoplastic injection, gas injection molding is applied and used to mold plastic parts from the application of high-pressure nitrogen.

Stack molds or multi-sided molds, unlike conventional injection molds, allow the multiplication of inlet cavities and, consequently, the increment of injected parts for each cycle.

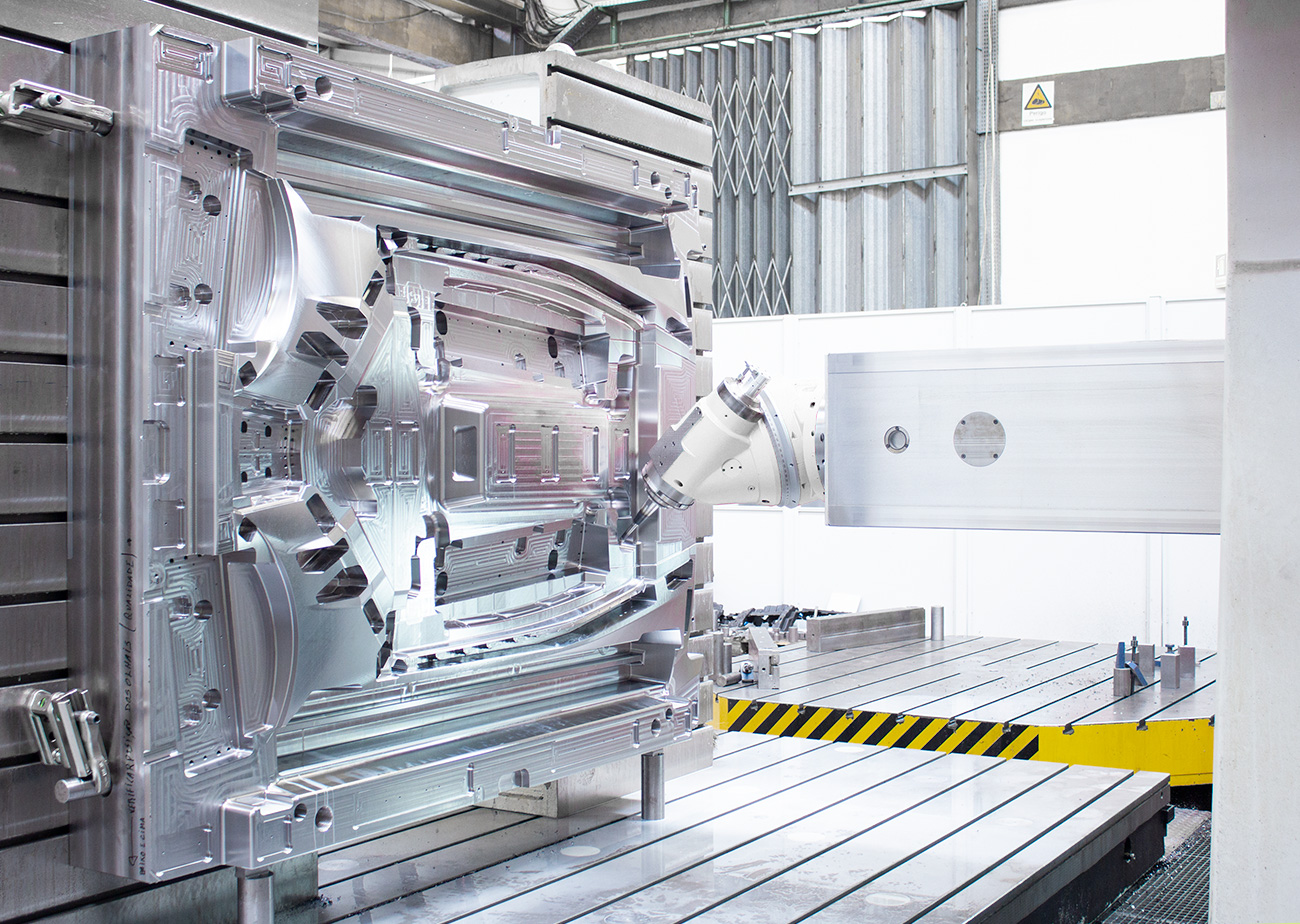

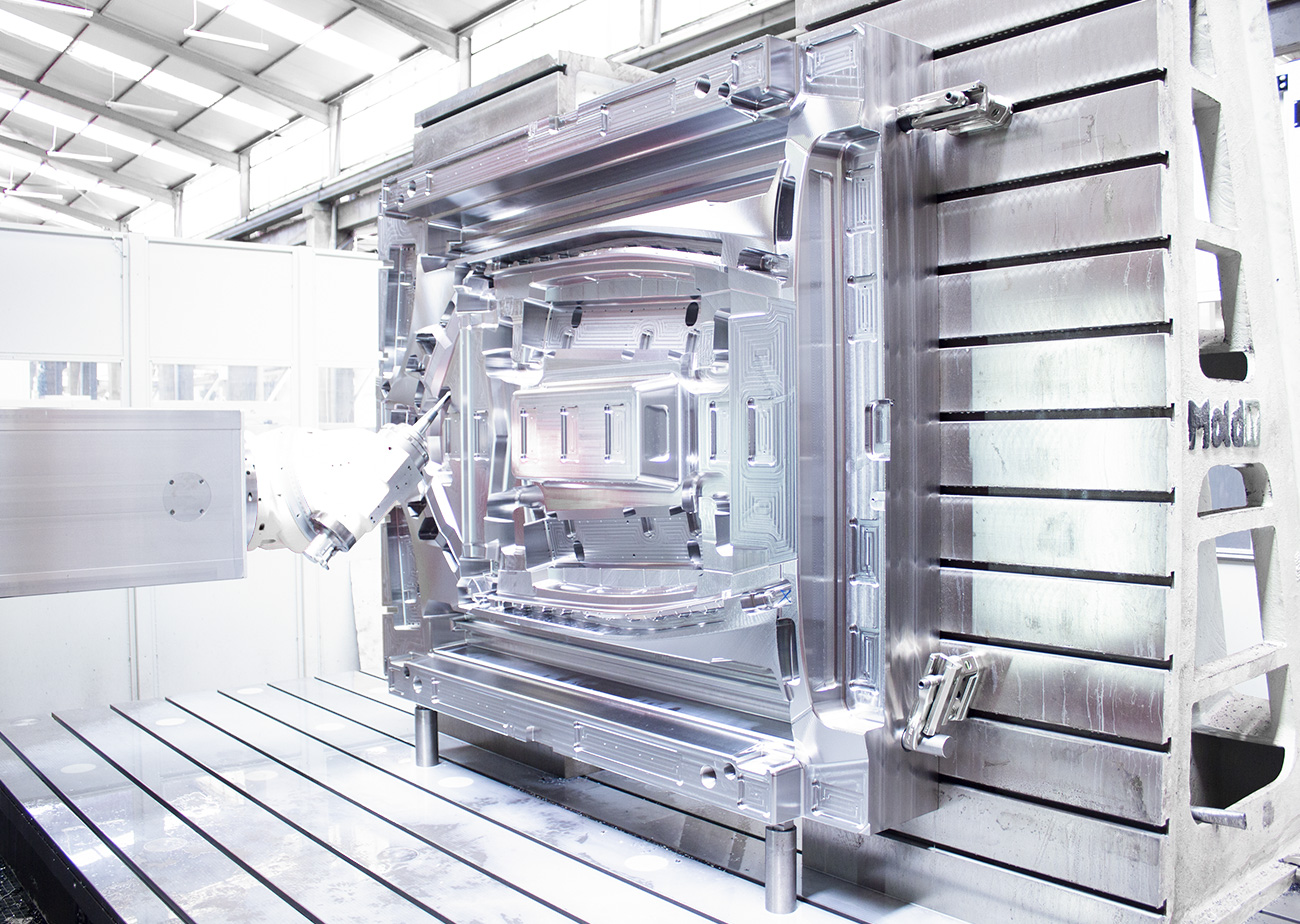

ABILITIES

8000 X 1600 X 3000 mm

TONELADAS

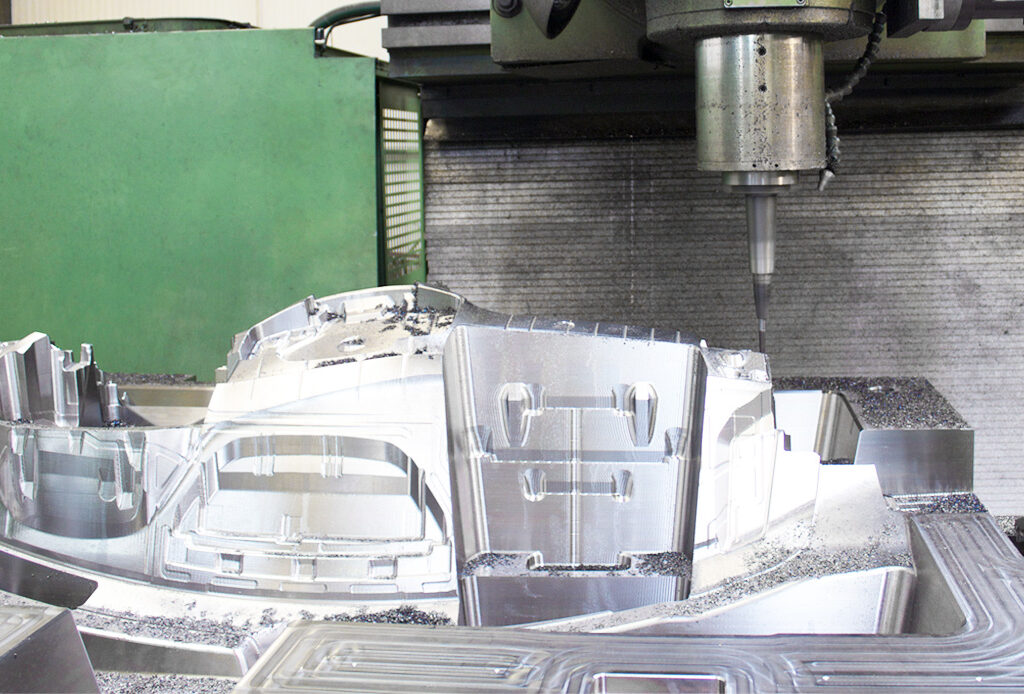

MILLING

Machining stations equipped with DEPOCAM software and 3 to 5-axis equipment.

EROSION

4-Axis CNC controlled equipment, automatic electrode feeding system and electrode management system from modelling to dimensional control.

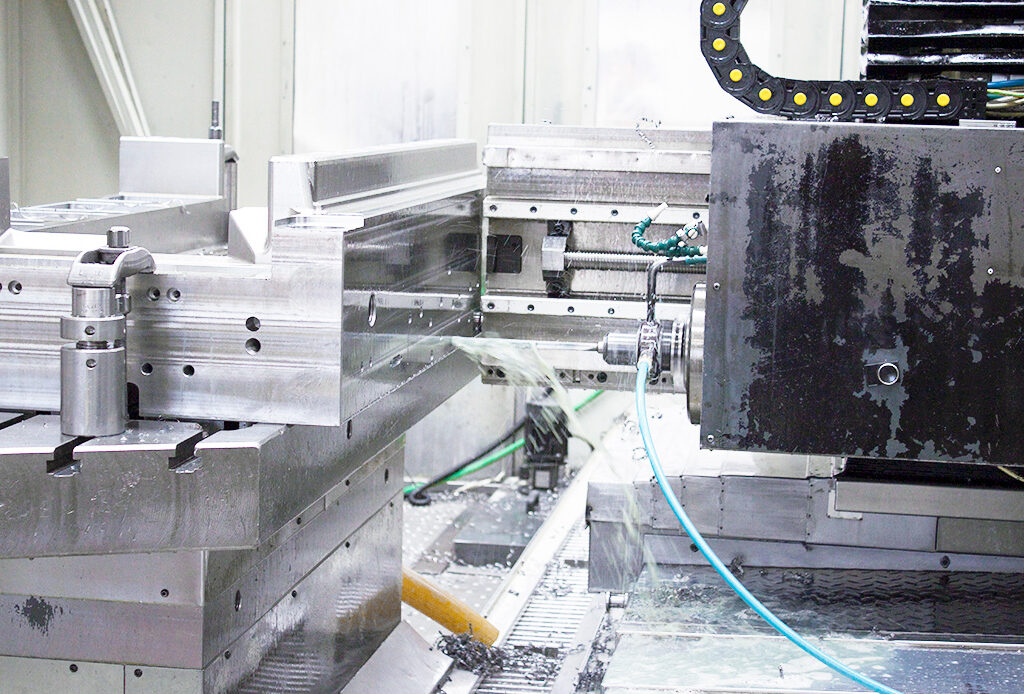

DRILLING

CNC drilling equipment with 6 controlled axes and programming software.

BENCH

Team with high experience and competence in various mold technologies.